Introduction

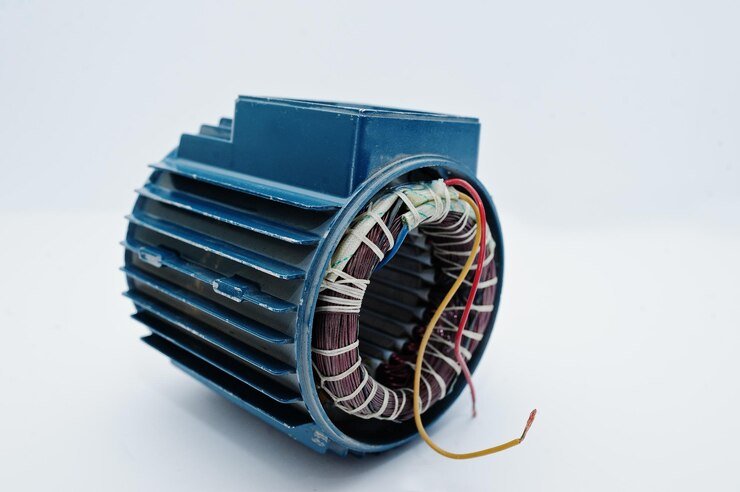

The Huck Spaulding Power Supply Rheostat is a specialized device used to regulate electrical current in power supply systems, offering precise control over voltage and resistance. Manufactured by Huck Spaulding, a reputable name in the field of electrical components, this rheostat plays a vital role in applications where adjustable resistance is needed to fine-tune the performance of electrical circuits. Known for its reliability and durability, the Huck Spaulding Power Supply Rheostat is commonly used in power supplies, industrial control systems, laboratory equipment, and other settings where precise electrical adjustments are necessary.

In this article, we will explore the key features, applications, working principles, installation process, and maintenance tips for the Huck Spaulding Power Supply Rheostat, showcasing its importance in modern electrical control systems.

1. Understanding the Functionality of the Huck Spaulding Power Supply Rheostat

The Huck Spaulding Power Supply Rheostat functions primarily as a variable resistor that is used to control the flow of electrical current through a circuit. Its core function is to adjust the resistance within an electrical system, which in turn controls the voltage and current distribution. The rheostat works by using a sliding contact or wiper mechanism that moves along a resistive element, either increasing or decreasing the resistance in the circuit, allowing the user to fine-tune the power supply to match the desired performance requirements.

This adjustability is crucial in various systems, as it provides the flexibility to modify current flow in real-time, making the rheostat an indispensable component in experimentation, testing, and process control. The Huck Spaulding model is particularly designed for high-precision applications, providing smooth operation, minimal wear and tear, and long-lasting performance.

2. Key Features of the Huck Spaulding Power Supply Rheostat

The Huck Spaulding Power Supply Rheostat offers several key features that make it an ideal choice for precise electrical control in both commercial and industrial settings. Some of the most notable features include:

- Adjustable Resistance – The rheostat allows for continuous resistance adjustment, enabling fine control over electrical parameters in various applications.

- High Durability – Designed with quality materials, the Huck Spaulding rheostat ensures longevity and reliability, even in harsh industrial environments.

- Smooth Operational Control – The sliding wiper mechanism ensures that users can make adjustments smoothly, preventing sudden power fluctuations that could damage sensitive equipment.

- Wide Voltage and Current Ratings – Suitable for use in high-voltage and high-current applications, ensuring versatility in its range of possible uses.

- Precision Calibration – The rheostat is designed to offer accurate and stable resistance adjustments, ensuring precise control in applications that require high accuracy.

These features make the Huck Spaulding Power Supply Rheostat a valuable tool in a wide range of electrical engineering and control applications.

3. Applications of the Huck Spaulding Power Supply Rheostat

The Huck Spaulding Power Supply Rheostat is used across a variety of industries and applications where precise control of electrical current is critical. Some common applications include:

- Power Supplies – In power supply units, the rheostat helps to regulate output voltage and current, ensuring that the connected system receives the correct power levels.

- Laboratory Equipment – Used in scientific and engineering laboratories, the rheostat provides adjustable resistance for conducting experiments and calibrations with variable electrical parameters.

- Industrial Control Systems – In manufacturing and automation, the rheostat is used to adjust the power levels supplied to motors, machines, and other equipment that require specific voltage or current settings.

- Testing and Calibration – In test benches and calibration setups, rheostats allow for fine adjustments in electrical measurements, ensuring accuracy in testing equipment and ensuring that it is properly calibrated.

- Audio Equipment – In audio amplifiers and sound systems, the rheostat is used to adjust volume levels, ensuring a consistent audio output across various components.

Given the versatility of the Huck Spaulding Power Supply Rheostat, it is often integrated into systems that require continuous adjustments and precise control over current flow and power distribution.

4. How the Huck Spaulding Power Supply Rheostat Works

The operation of the Huck Spaulding Power Supply Rheostat is relatively straightforward. It is built with a resistive element (usually made of carbon or metal oxide) and a wiper or slider that moves across the resistive material. As the wiper is adjusted, the effective length of the resistive element changes, which in turn alters the total resistance in the circuit.

- Increasing the resistance – As the wiper moves along the resistive element towards a higher resistance area, it reduces the current flow in the circuit.

- Decreasing the resistance – When the wiper moves towards the lower resistance end, it allows for an increase in current flow, providing more power to the connected load.

This continuous adjustment capability gives users the ability to fine-tune the system for optimal performance, ensuring that electrical components receive the right voltage and current for proper operation.

5. Installing the Huck Spaulding Power Supply Rheostat

Installing the Huck Spaulding Power Supply Rheostat requires careful attention to ensure proper functionality and long-term performance. Here’s a general overview of the installation process:

- Mount the Rheostat – The rheostat should be mounted in an accessible location within the power supply system, ensuring that the resistive element is properly secured.

- Connect the Wiring – Properly wire the rheostat into the circuit to ensure that it is placed in series or parallel with the load, depending on the specific configuration required for the application.

- Verify Connections – Ensure that all electrical connections are secure, with no loose or exposed wires that could lead to short circuits or power loss.

- Calibrate the Rheostat – Before using the rheostat, it is important to calibrate it to ensure that it provides accurate resistance values and operates within the specified range.

After installation, it is important to test the system to ensure that the Huck Spaulding Power Supply Rheostat is functioning correctly, and the electrical parameters are within the required specifications.

6. Maintenance Tips for the Huck Spaulding Power Supply Rheostat

To ensure that the Huck Spaulding Power Supply Rheostat continues to function optimally over time, regular maintenance is necessary. Here are some tips to maintain the performance of your rheostat:

- Keep the Rheostat Clean – Regularly clean the resistive element and sliding contact to prevent dust and debris buildup, which can affect the rheostat’s performance.

- Inspect for Wear – Over time, the resistive element and wiper mechanism may experience wear. Check for friction damage or wear spots on the surface and replace parts as needed.

- Lubricate the Sliding Mechanism – Ensure that the wiper or sliding mechanism operates smoothly by applying appropriate lubrication. This will prevent wear and ensure the rheostat operates without hindrance.

- Check for Electrical Connections – Regularly inspect all wiring and connections to ensure that they remain tight and free of corrosion.

By following these simple maintenance guidelines, the Huck Spaulding Power Supply Rheostat can continue to provide precise control for many years, reducing the need for frequent replacements or repairs.

Conclusion

The Huck Spaulding Power Supply Rheostat is an essential component for precise electrical control, widely used in a range of industrial, scientific, and commercial applications. Its variable resistance, durability, and smooth operation make it an ideal choice for situations requiring adjustable current flow.